At a Glance

-

8.5K

Square Metres

- Location

- United Arab Emirates

- Offices

-

-

Ratings

-

2 Pearls Estidama

-

Award

-

MEED Project Awards, 2021 National Winner - Industrial Project of the Year

- Location

- United Arab Emirates

- Offices

- Ratings

- 2 Pearls Estidama

- Award

- MEED Project Awards, 2021 National Winner - Industrial Project of the Year

Share

Project Silk

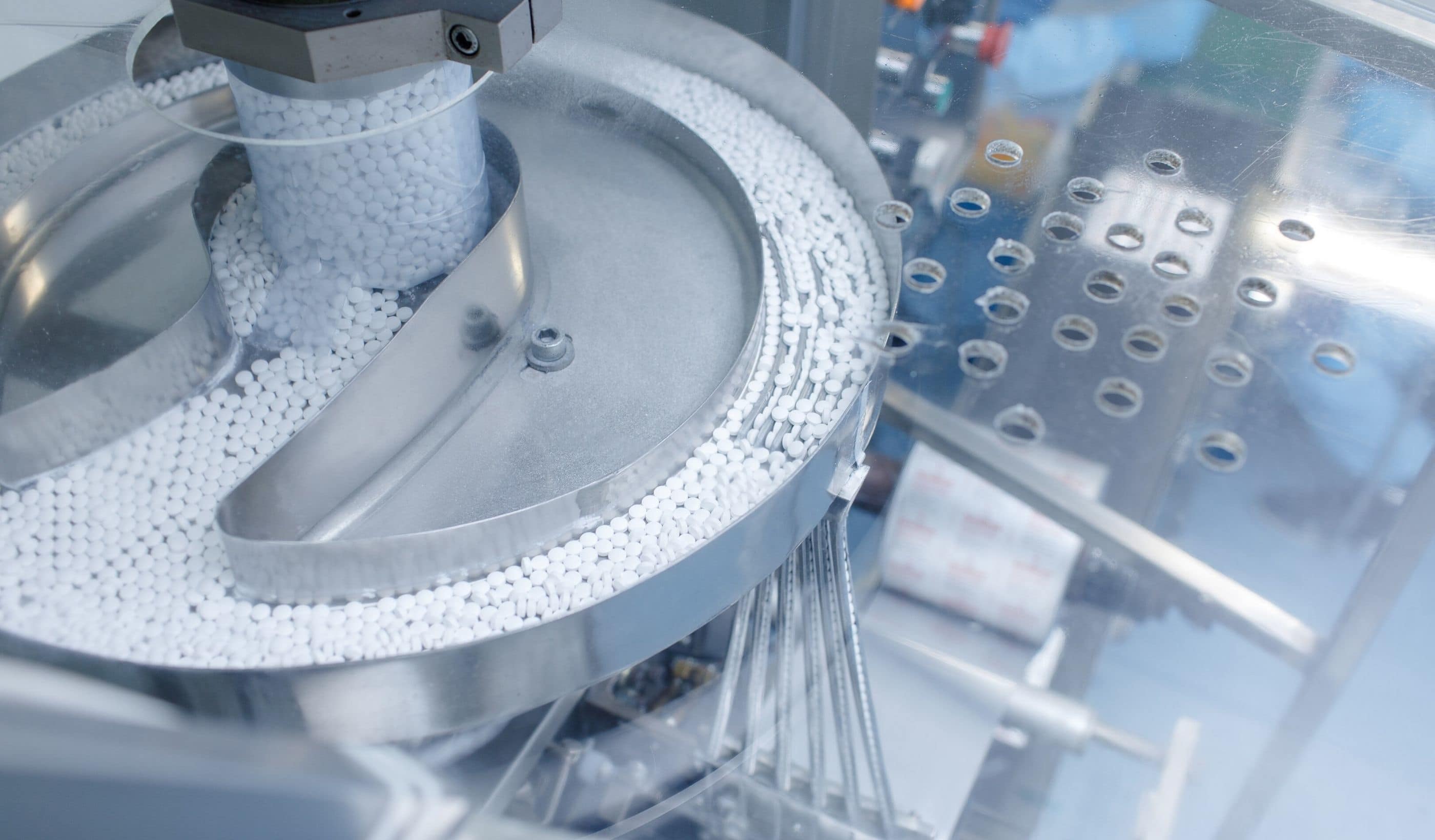

Project Silk included the design and construction of a purpose-built facility to manufacture unidirectional tape—a toughened epoxy pre-impregnated carbon fiber resin system (prepreg) that satisfies the requirements of a 20-year contract with a world-leading aircraft manufacturer.

Stantec provided the preliminary design and was retained as the technical advisor during this design-build project. As the product is sensitive to foreign object debris (FOD), the facility was designed to minimize contamination in the manufacturing spaces. The design and construction also addressed local climatic conditions including relatively extreme heat, low humidity, and significant fine airborne sand/dust and prevented adverse effects to the product or manufacturing equipment and support systems. The facility can produce nearly 1 million pounds (454,000 kilograms) of prepreg product (in a variety of sizes) each year that meets the end users’ stringent requirements.

By breaking new ground, Project Silk has shown what is possible in the region. The design and delivery of such an advanced facility also shows the possibilities opened by new construction technologies and close collaboration.

At a Glance

-

8.5K

Square Metres

- Location

- United Arab Emirates

- Offices

-

-

Ratings

-

2 Pearls Estidama

-

Award

-

MEED Project Awards, 2021 National Winner - Industrial Project of the Year

- Location

- United Arab Emirates

- Offices

- Ratings

- 2 Pearls Estidama

- Award

- MEED Project Awards, 2021 National Winner - Industrial Project of the Year

Share

Dave Calder, Vice President, Regional Growth Leader, Buildings (Global)

My job is to listen to my clients and figure out what their needs are to see if, and how, Stantec can help them.

Kevin Christon, Regional Director, Buildings MENA

I believe that success is created by carefully listening to our clients and turning their vision into a reality everyone can be proud of.

Akhilesh Nair, Head of Building Services Department

I strive to transform spaces into comfortable, healing environments while delivering exceptional engineering services.

Sy Selick, Principal, Operations Leader, Buildings (British Columbia)

I strive to develop integrated design solutions that help my clients meet their business goals.

Abdelazim Sherif, Senior Associate, Manager - Structures

Structural design for us means support—supporting loads, supporting other disciplines, and supporting innovative ideas.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.