- Location

- Guiyang City, Guizhou Province

- Offices

-

- Location

- Guiyang City, Guizhou Province

- Offices

Share

Energy Assessment for Safran

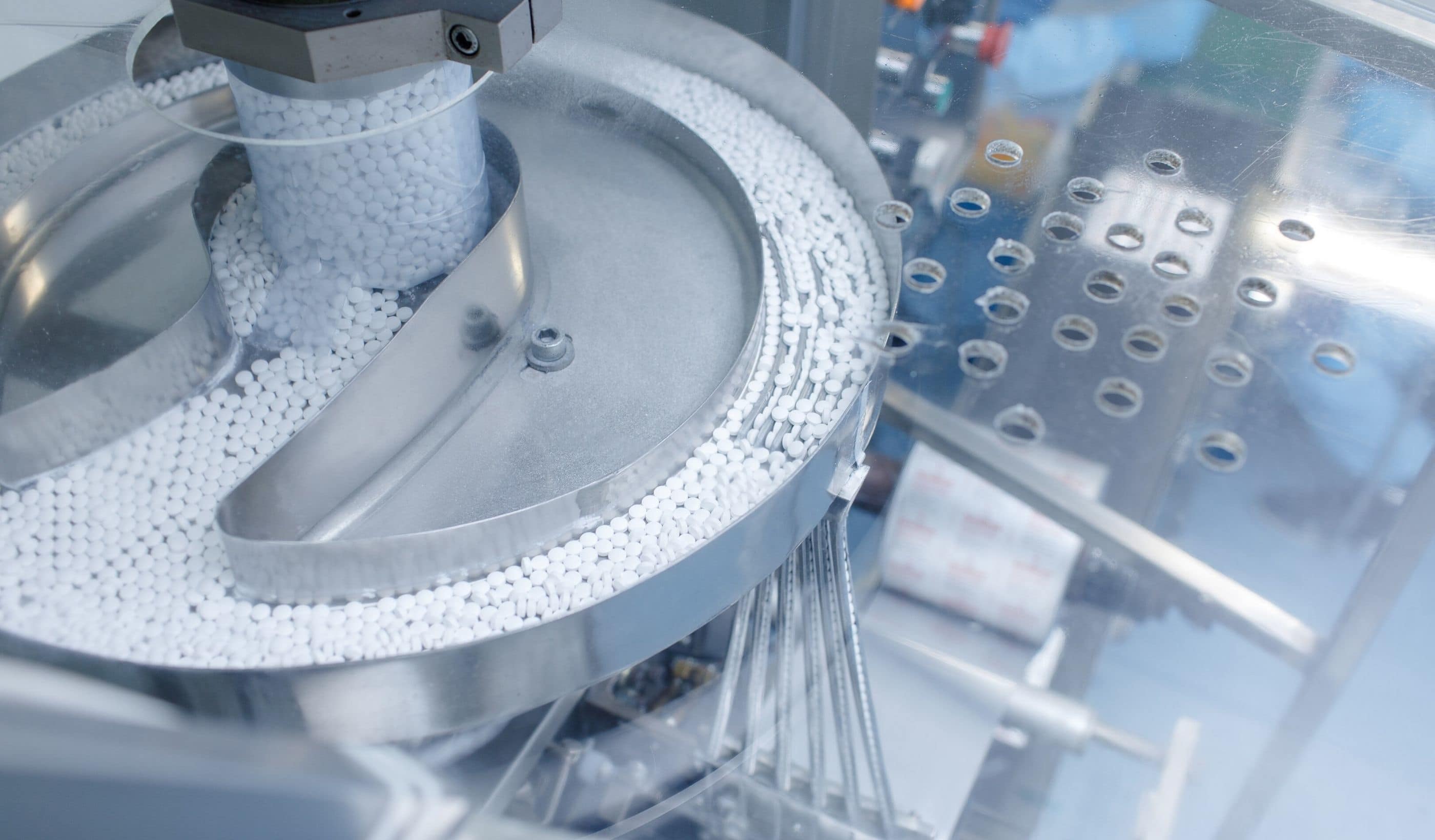

Located in Guiyang, in the heart of the High-Tech Industry Development Zone, Safran produces low-pressure turbine blades, seals, and vanes for CFM56 and LEAP aircraft engines by a lost wax casting process. The plant covers an area of more than 10,000 square metres (108,000 square feet).

When Safran wanted to conduct an energy audit that would help gain a better understanding of how energy is used within their plant, Stantec was commissioned to undertake the study and identify opportunities for improvement and energy saving. We conducted an energy survey to define the system boundary, identify unit processes, quantify energy supply, and allocate energy use to different unit processes.

We also conducted an energy analysis to identify system errors and detail problems, idling power and energy, systems that are far from best available technology (BAT), mismatching energy quality, barriers, and driving forces. Altogether, that made the potential for energy efficiency and conversion for the entire system clear. Based on these activities, we proposed measures that would identify possible solutions, calculate solution impacts, and measure the economic impact for the client.

The result? Our services have helped Safran maintain an overall picture on their energy consumptions and contributed to the design of their energy efficiency program—therefore reducing the site’s energy consumption.

- Location

- Guiyang City, Guizhou Province

- Offices

-

- Location

- Guiyang City, Guizhou Province

- Offices

Share

Jacky Zhang, Principal Consultant

I believe my environmental work protects our future and helps our clients commercially. You can protect the earth and enable clients to have commercial benefit.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.