- Location

- St. Johns, New Brunswick

- Offices

-

- Location

- St. Johns, New Brunswick

- Offices

Share

Tissue Machine Replacement

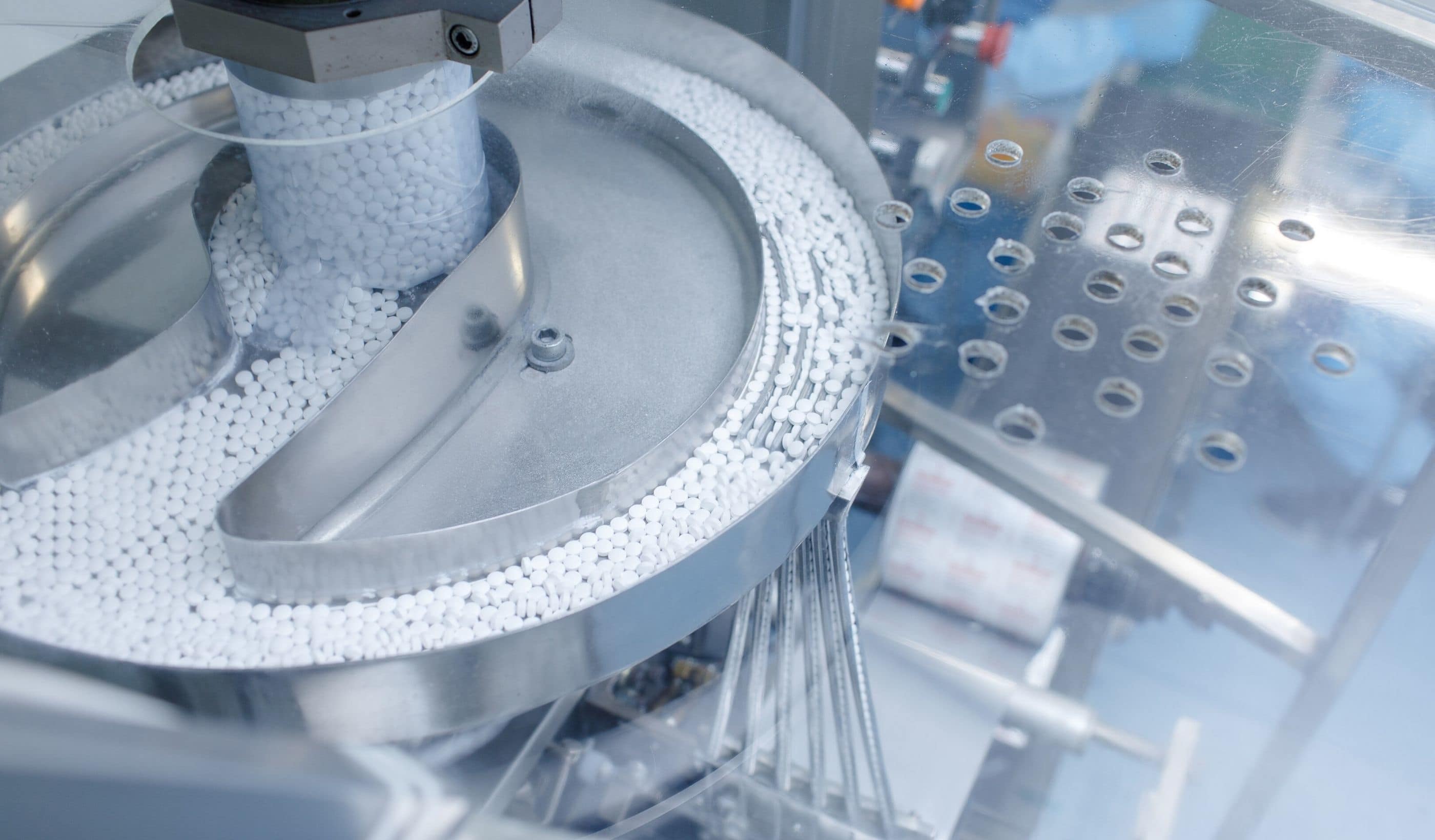

Our client needed to replace an existing 128-inch (325-centimetre) trim, single-layer headbox Fourdrinier tissue machine. We worked with the client from the conceptual phase (including detailed cost estimates) through to detailed design, construction, start-up and commissioning for installation of a new 5,000 feet per minute crescent former tissue machine.

We also provided dynamic process modeling, equipment sizing and selection, 3D modeling for virtual walkthroughs, construction planning and progress reporting. Engineering was also provided for balance of plant services to support the changes to the mill resulting from the new machine.

The new machine is a Metso Crescent Former with a 2-ply headbox, felt section, Yankee hood air system reel, and unwind stands. Meeting a 30-day turnaround, the project was completed on schedule and on budget while exceeding quality and production targets.

- Location

- St. Johns, New Brunswick

- Offices

-

- Location

- St. Johns, New Brunswick

- Offices

Share

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.