- Location

- Italy

- Offices

-

- Location

- Italy

- Offices

Share

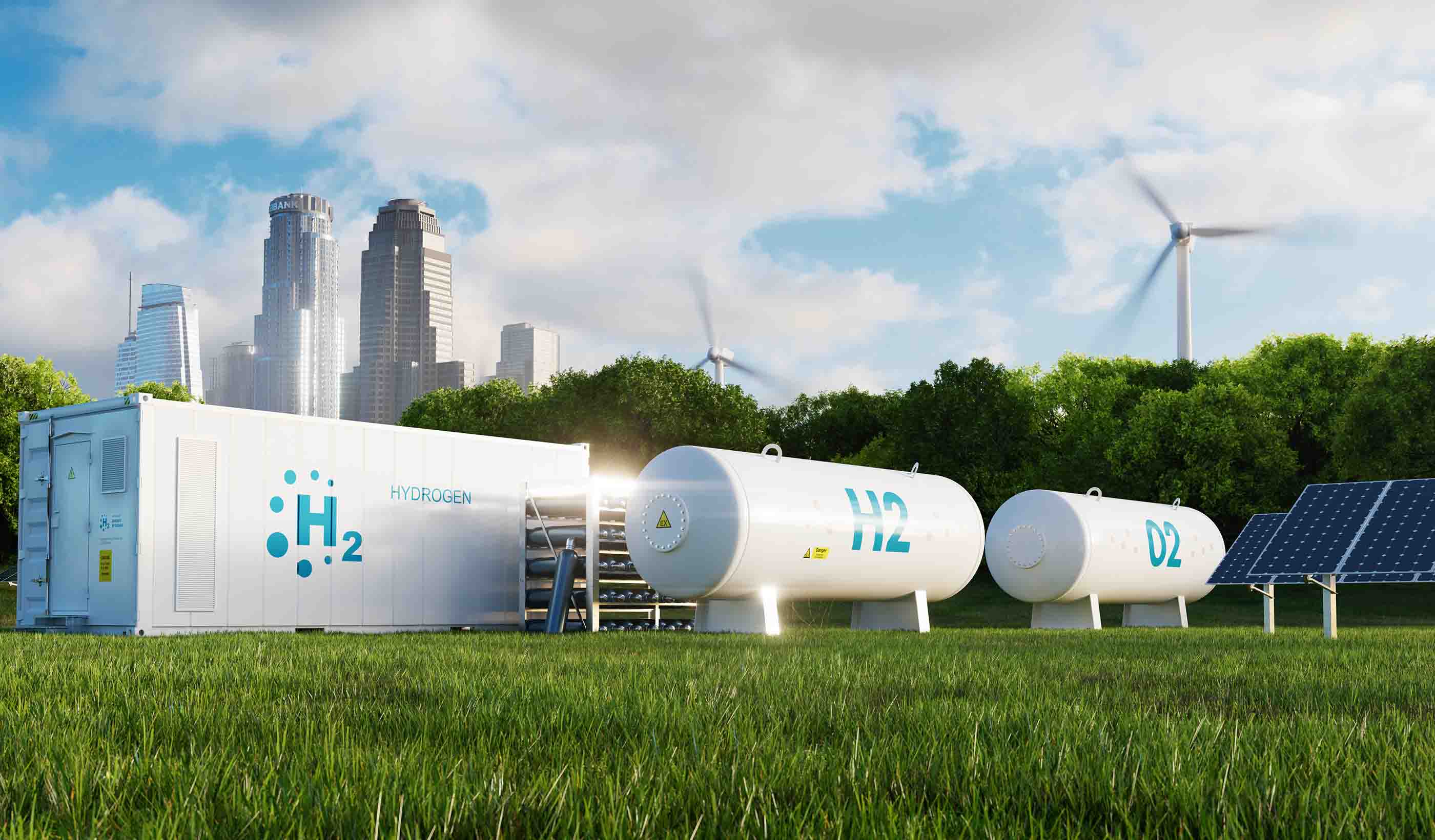

4MW Green Hydrogen Plant

In alignment with its company decarbonatisation goals, our client in Italy was planning to develop a 4MW hydrogen production plant to test and validate innovative technologies used in the production and storage of green hydrogen. The goal was also to determine the most cost effective of these technologies.

The components being tested by our client include various electrolyser types, battery configurations, and storage options like metal organic frameworks (MOFs) and liquid hydrogen organic carriers (LOHFs) along with valves, instrumentation, and materials. Our team was engaged to support this initiative, initially by reviewing the production site and providing geotechnical and environmental assessments, factor inputs, and permitting. The client later added the assessment of plant heat balance to our scope. Currently, we are providing scoping and engineering expertise on the electrolyser integration as well as reviewing and making a recommendation for the hydrogen distribution.

The recommendations presented by our team will provide our client with a deeper understanding of current green hydrogen production costs. They will also earn insight into how these costs can be reduced for future production projects and help them achieve their decarbonisation goals.

- Location

- Italy

- Offices

-

- Location

- Italy

- Offices

Share

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.