At a Glance

-

$50M

Construction Value

-

50

Metres Deep

-

3.7KM

Long

- Location

- Toronto, Ontario

- Offices

-

- Location

- Toronto, Ontario

- Offices

Share

Western Beaches Tunnel Pumping System Improvements

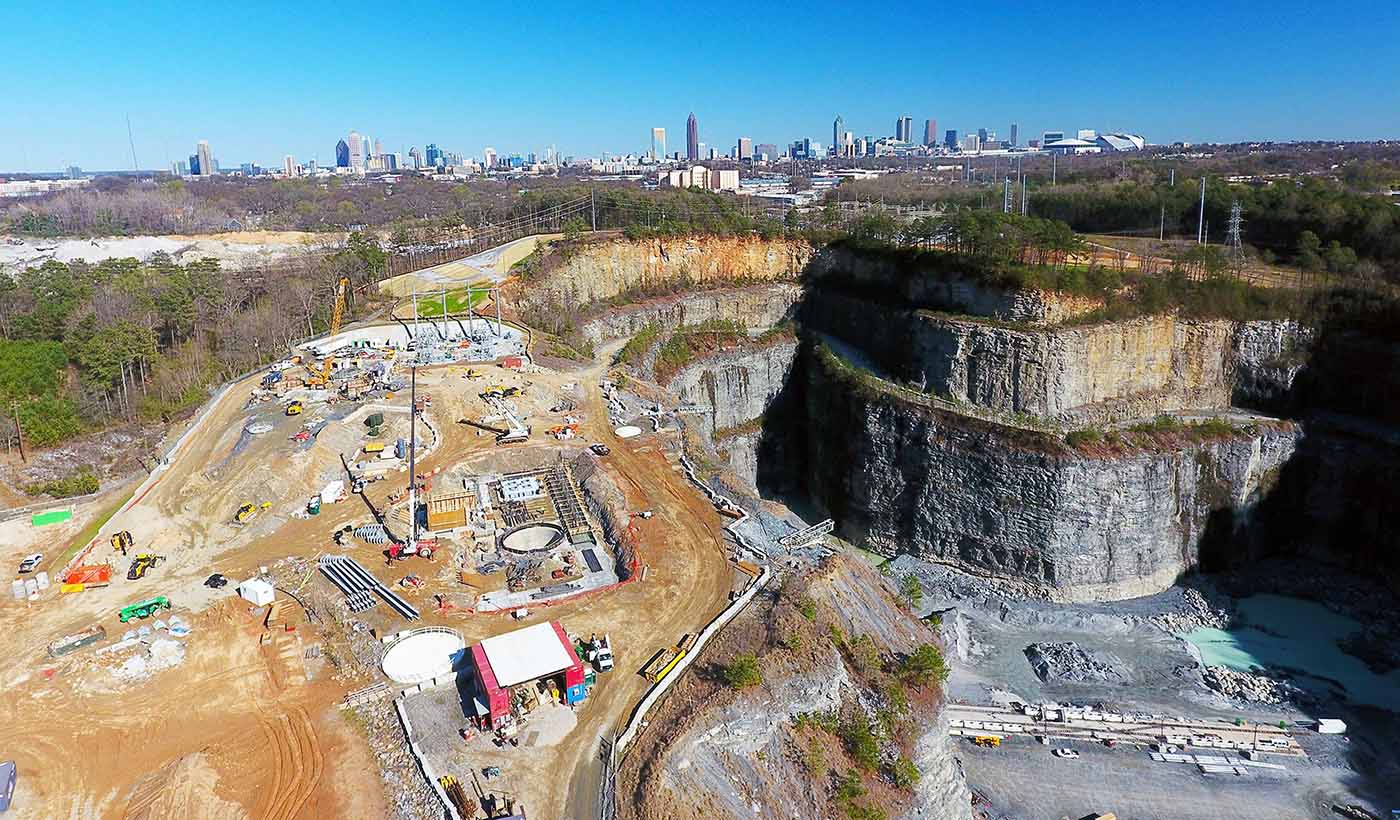

The Western Beaches Tunnel was constructed in 2000 to reduce the discharge of untreated storm water and combined sewer overflows (CSO) into Lake Ontario. It collects, stores, and treats CSOs from 10 sewer outlets before they reach the lake. The system consists of three large vertical shafts up to 50 m deep and multiple smaller drop shafts inter-connected by a 3.7 km long tunnel, providing a capacity of 85,000 m3.

Numerous problems plagued the pumping system due to the large range of operating conditions required by the existing configuration, including inability of the pumps to empty out stored CSO flows, inadequate sediment flushing and removal, flow surges causing damage to the structures, and flooding of surrounding areas—and, it failed after the first storm event. Solutions were needed—quickly. We saw an immediate need to simplify the configuration to provide better functionality, control, and operation. The preliminary design phase included a structural condition assessment of the 3.7 km long tunnel and three 27 m dia./50 m deep storage shafts, and a condition assessment and review of existing infrastructure and original design. A detailed investigation of options for pumping solutions was undertaken and settled on a two-stage configuration to allow cleaner supernatant to be pumped to the UV system, with remaining contents being pumped to the sewer for further treatment. Computational Fluid Dynamics (CFD) modeling was undertaken of the existing and proposed sediment flushing and a new sediment fluidization system was designed.

The chosen solutions included installation of new shaft dewatering pumps with capacities up to 43 ML/d and addition of dedicated grit/debris pumps located at the bottom of the shaft, new instrumentation, and upgrades to the UV disinfection system. We also inspected and helped improve the three shafts and tunnel. A new sediment fluidization system was designed using Computational Fluid Dynamics modeling. Upgrades to other building systems support the system improvements. The Phase 1 construction contract included all sewer chamber modifications, adjustable weirs at all nine lake isolation points, and construction of the new flushing pump and valve chamber. The Phase 2 construction contract will include the remaining upgrades for the pumping station.

At a Glance

-

$50M

Construction Value

-

50

Metres Deep

-

3.7KM

Long

- Location

- Toronto, Ontario

- Offices

-

- Location

- Toronto, Ontario

- Offices

Share

Susan Alarcon, Senior Associate, Water

Our team brings valuable water solutions and resources to communities across Ontario, improving the quality of life for everyone living there.

Jian Li, Principal, Business Centre Practice Leader, Water

My focus—service, performance, and the team. Providing practical engineering solutions to environmental challenges in our communities.

Fangbiao Lin, Vice President, Global Practice Leader for Environmental Hydraulics

CFD modeling is my passion, solving flow problems is my satisfaction!

Steve Fradkin, Senior Principal, Tunneling & Trenchless Subsector Leader

Although the work and results are generally unseen, the results of my work benefit everyone.

Dave Eadie, North American Discipline Leader, Urban Water Resources

You must fully understand the problem before you can find the most effective fit-for-purpose solution.

Valery Woloshyn, Regional Delivery Leader

My work combines my love of the environment, problem solving, and teamwork. Trust and mutual respect are the heart of successful projects.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.