At a Glance

-

2

MLPA

- Location

- Australia

- Offices

-

- Location

- Australia

- Offices

Share

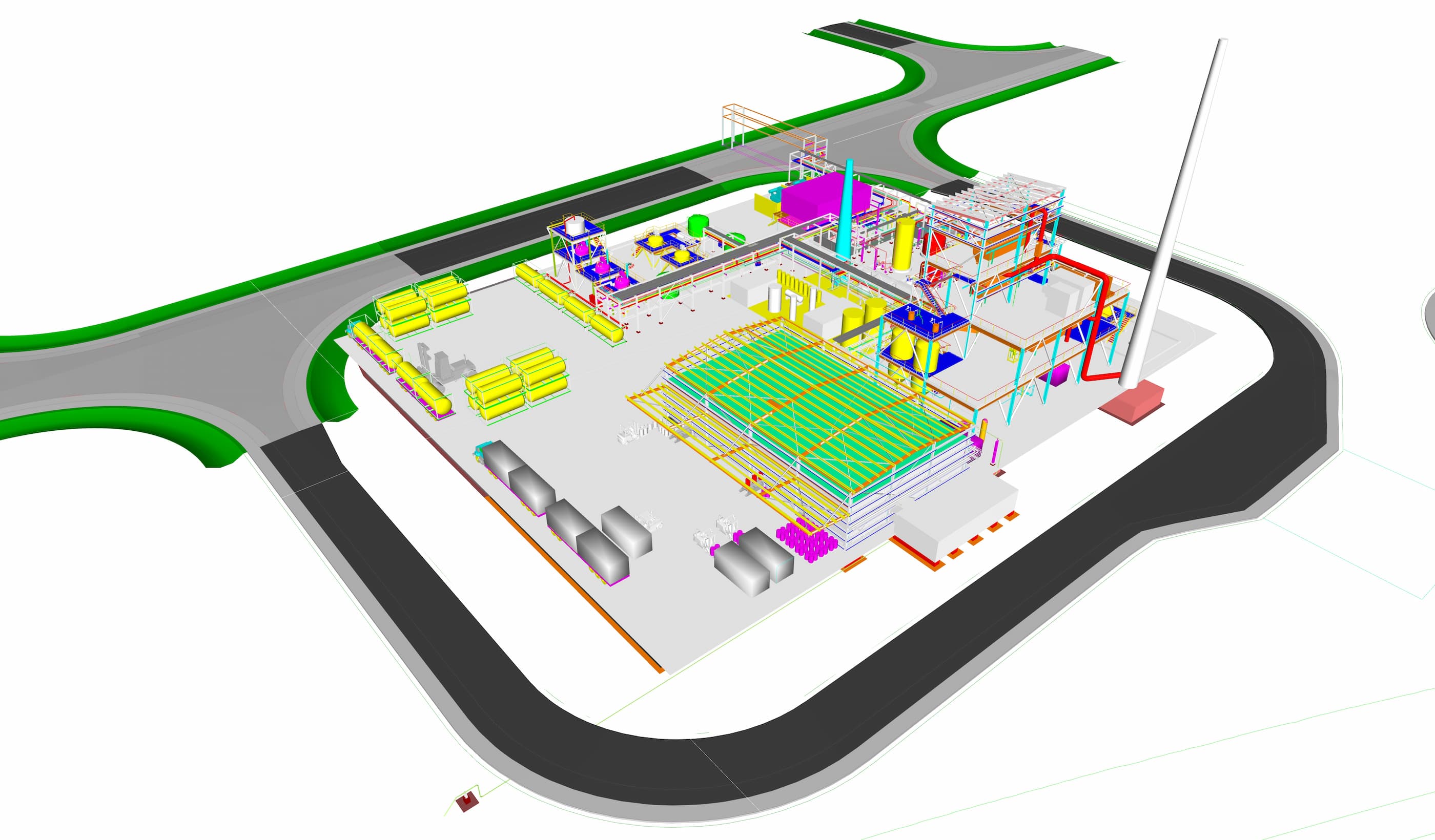

Vanadium Electrolyte Plant – EPCM

Vanadium redox flow batteries (VRFB) are one of the lowest carbon footprint batteries on the market. They’re typically used for energy storage like power plants and electrical grids. A key component of VRFB is vanadium, which must be mined and passed through a process plant to create vanadium electrolyte.

We provided engineering procurement and construction management (EPCM) services for a two mega-litre per annum (MLPA) vanadium electrolyte plant for production of battery electrolyte. The initial design was for a generic plant to ascertain the footprint and other key site requirements. Once a final site was selected, we were able to rapidly commence construction. The generic design became the template for future plants of a similar capacity.

The benefits of VRFB’s are immense. Aside from having minimal maintenance requirements, they have a much longer life cycle than other types of batteries, lasting more than 20 years. Thanks to our global Mineral Processing Centre of Excellence in Brisbane, we were able to support the growing demand for VRFB’s throughout the world.

At a Glance

-

2

MLPA

- Location

- Australia

- Offices

-

- Location

- Australia

- Offices

Share

Damian Pianta, Project Manager

There is nothing more satisfying than improving safety for our clients and employees.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.