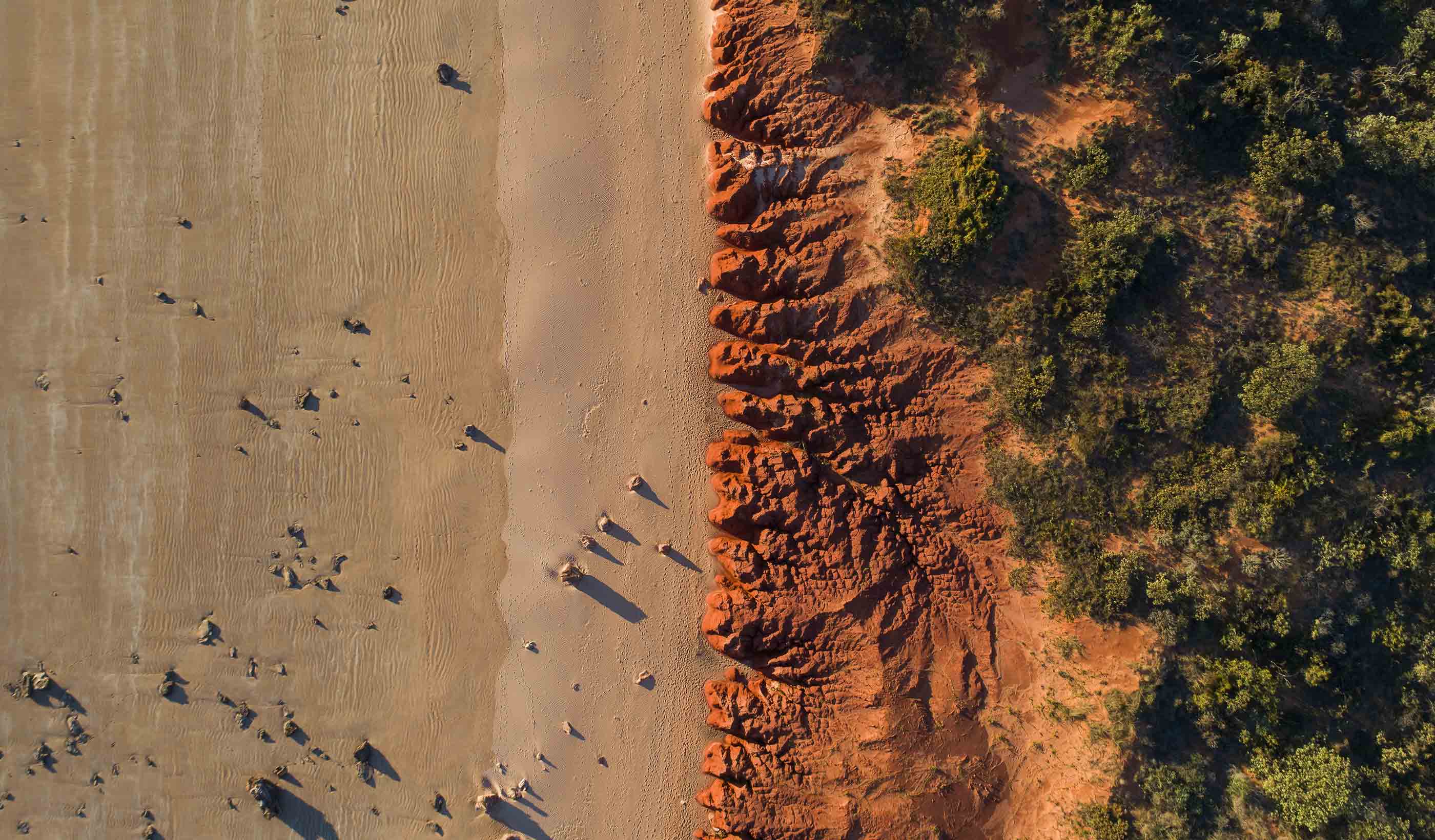

Mine Process Plants

Using all we know to optimise process flow

We understand that the basis for all mining project development is founded on a good process flow diagram. Stantec can aid you in developing a robust flow sheet for your processing requirements, as well as determination of recovery rates, process plant layout and size, establishment of operational sampling and analysis criteria, and capital and operating cost estimates.

Our process design and engineering specialists work across a range of commodities such as iron ore, manganese, mineral sands, nickel, copper, diamonds, coal, gold, and other precious and base metals. From simple crushing and screening circuits to more complex mineral processing plants—particularly where beneficiation is required through various forms of separation such as gravity, flotation, magnetism, or leaching —we've got you covered.

We will streamline your process plant, supplying maximum production output for the least operational cost. We can also help with removing bottlenecks and plant optimisation.

Metallurgical testwork and lean process design

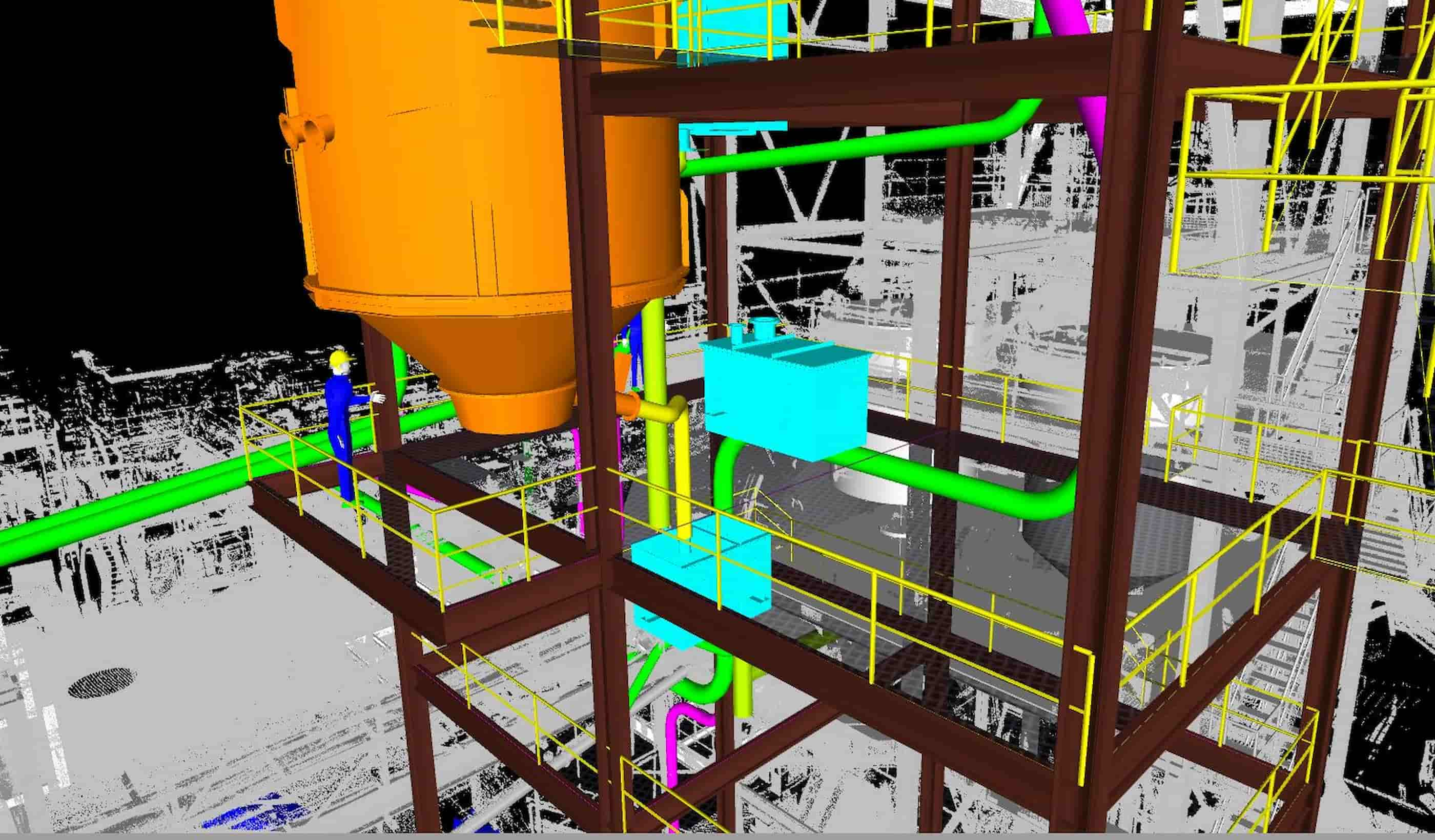

Our team of experts will help you determine your ore’s performance through metallurgical testwork performed to exacting standards. We will help you decide the product grade, recovery rate, and scale of the processing operation you need.Engineering design using the latest software

We utilise the latest 3D modelling software for each project phase, from as early as conceptual design. This integrated approach to engineering helps us to coordinate disciplines and improve efficiency in design.Bikram Singh, Business Leader, Energy & Resources WA

Communicating changes to the client timeously is key to meeting targets and maintaining a positive working relationship.

Jeremy Tape, Discipline Leader, Process

Acquire practical experience. It's essential to recognise that your design will impact others.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.