At a Glance

-

$30M

AU in Construction

- Location

- New South Wales, Australia

- Offices

-

- Location

- New South Wales, Australia

- Offices

Share

Copper Concentrator Plant Semi-Autogenous Grinding Mill Upgrade

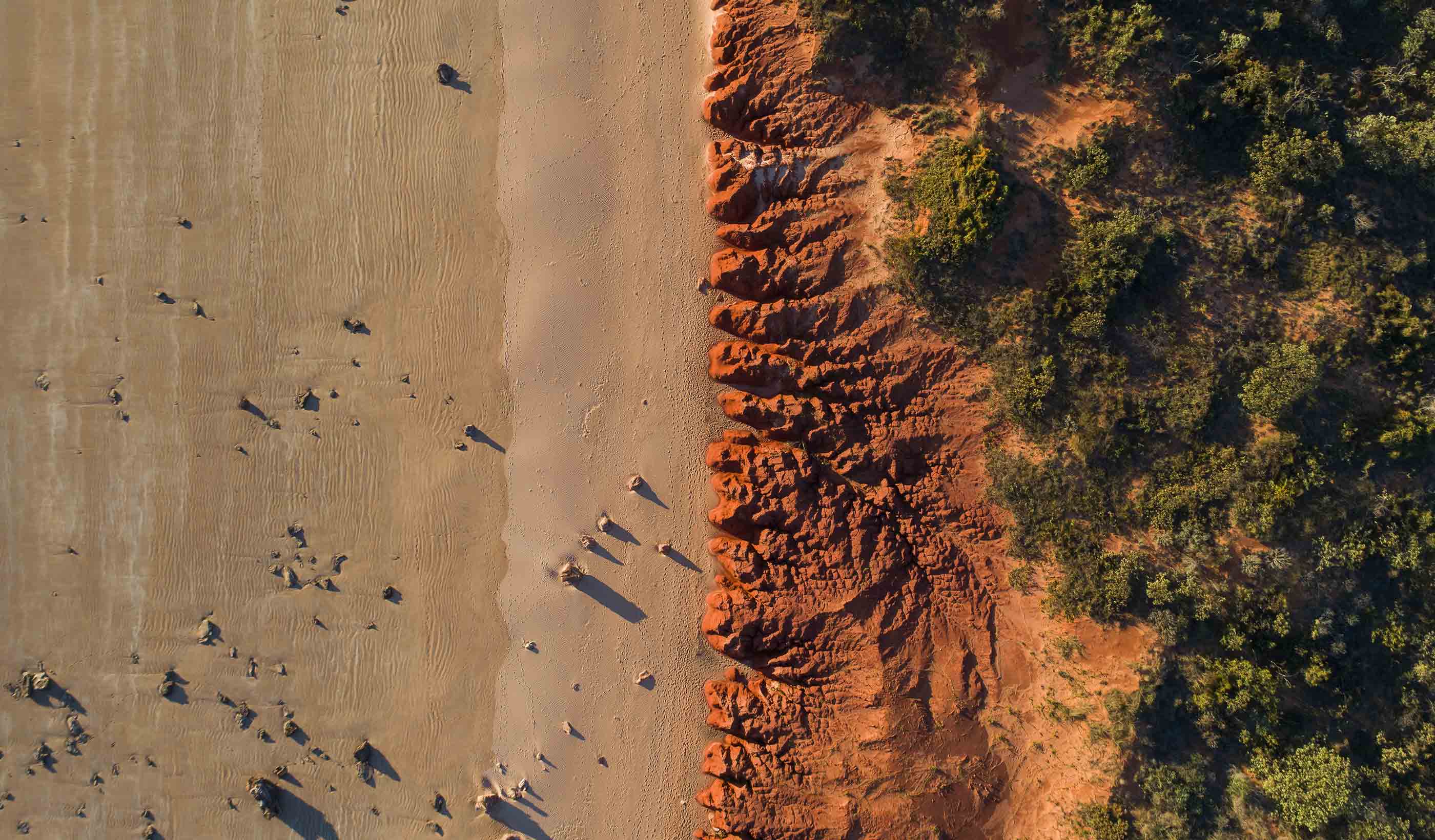

Located in New South Wales, a copper mine required a significant upgrade of its copper concentrator plant by replacing two semi-autogenous grinding (SAG) mills. The original SAG mills were installed in the late 1960s and have operated reliably for over 55 years, clocking up an estimated 270 million revolutions. However, cracking in the outer shell determined that repairing them was not an economical option, prompting the need for an upgrade.

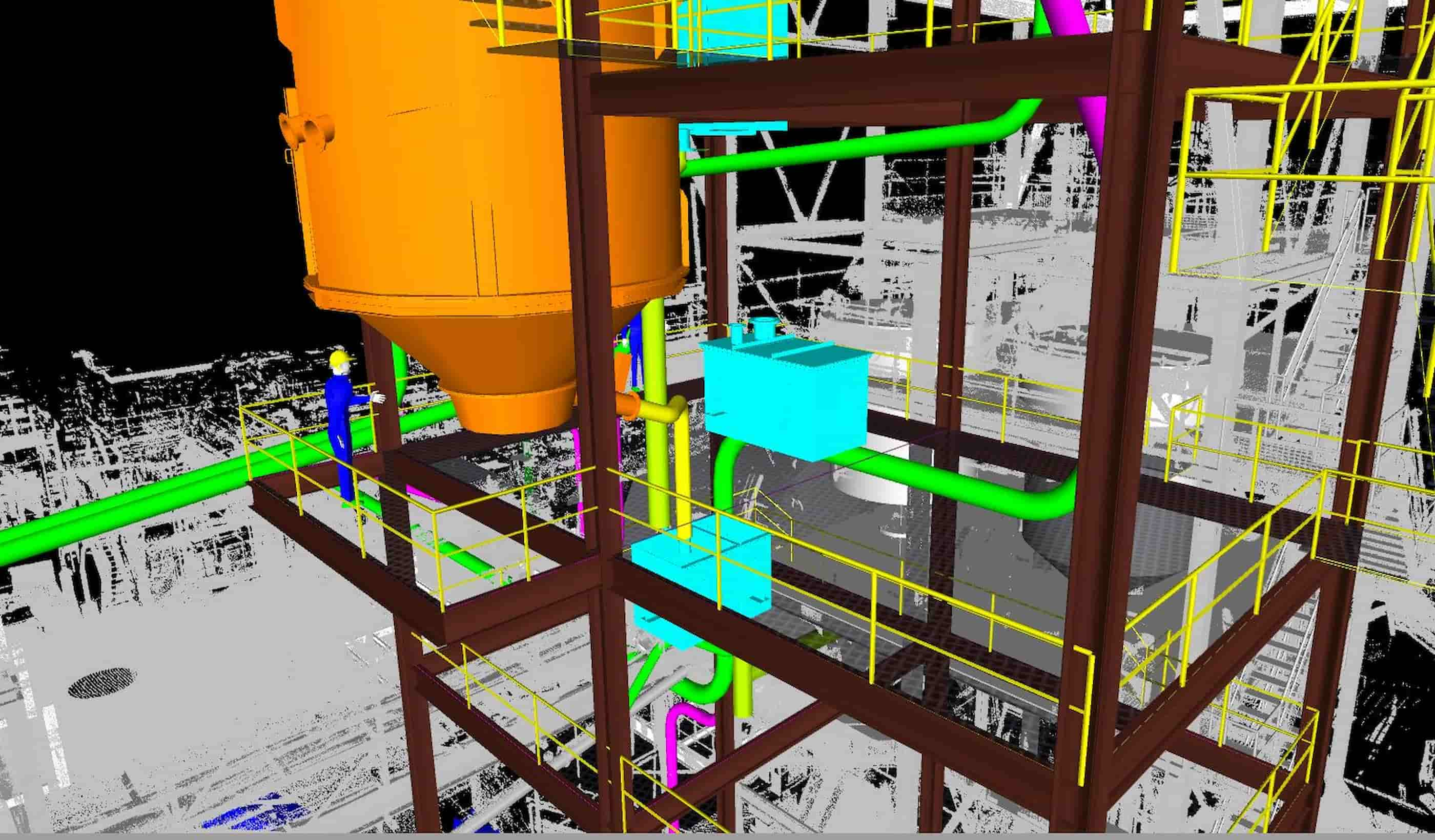

Our team provided the engineering design and commissioning support to upgrade the new mills. Replacing the mills posed some challenges including working within tight timeframes to minimize production downtime. To overcome this, we provided flexibility with the timing of commissioning services to support the mill’s outages and detailed scanning and 3D modelling of the mills to increase design process efficiencies.

The new mill designs take advantage of modern technology and introduce variable speed drives as well as safety and maintenance improvements.

At a Glance

-

$30M

AU in Construction

- Location

- New South Wales, Australia

- Offices

-

- Location

- New South Wales, Australia

- Offices

Share

Scott Haydon, Lead Designer

I enjoy converting engineering into drawings that convey design intent to the end user—providing a valuable contribution to any project.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.

.jpg)