- Location

- Western Australia

- Offices

-

- Location

- Western Australia

- Offices

Share

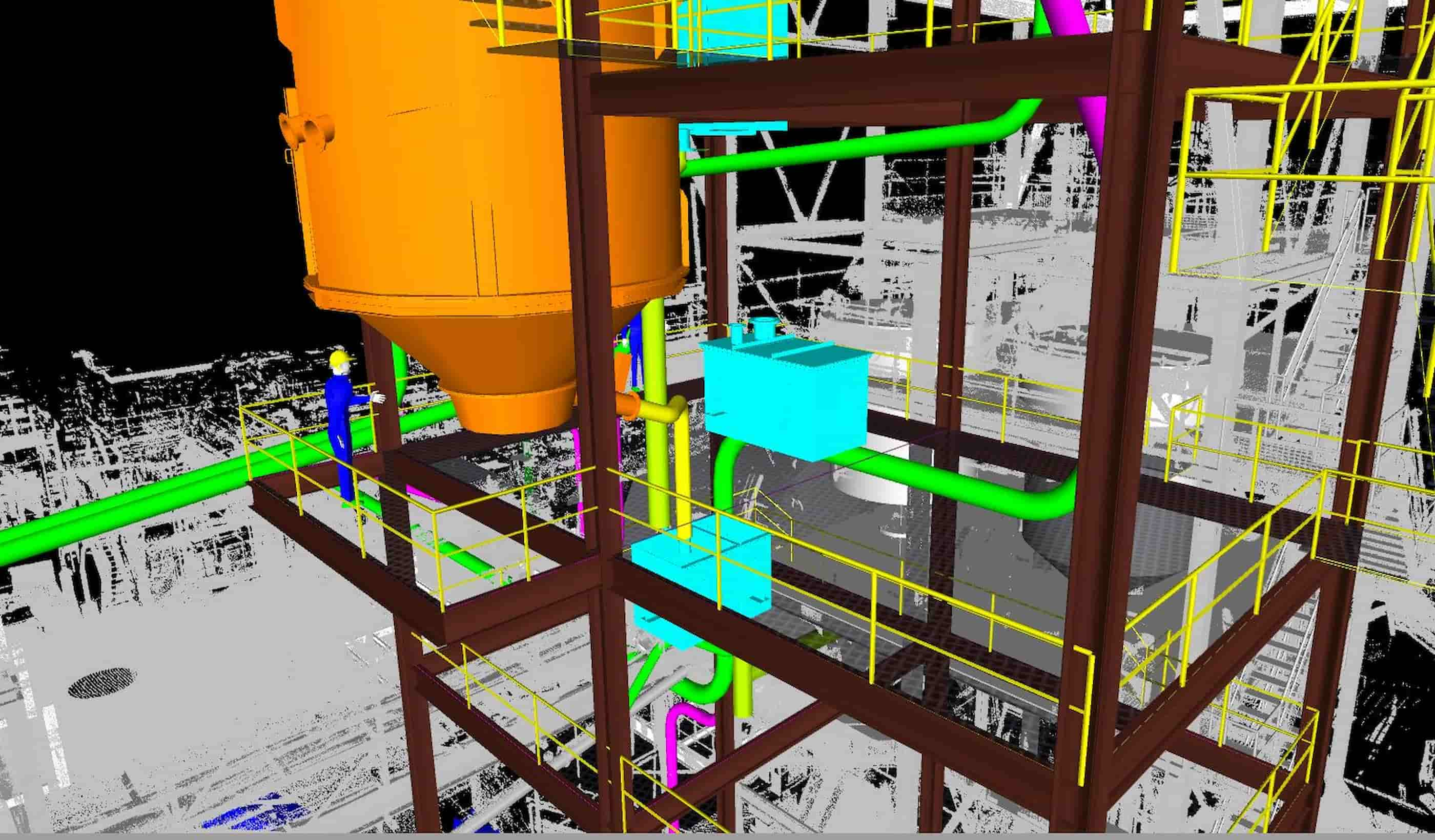

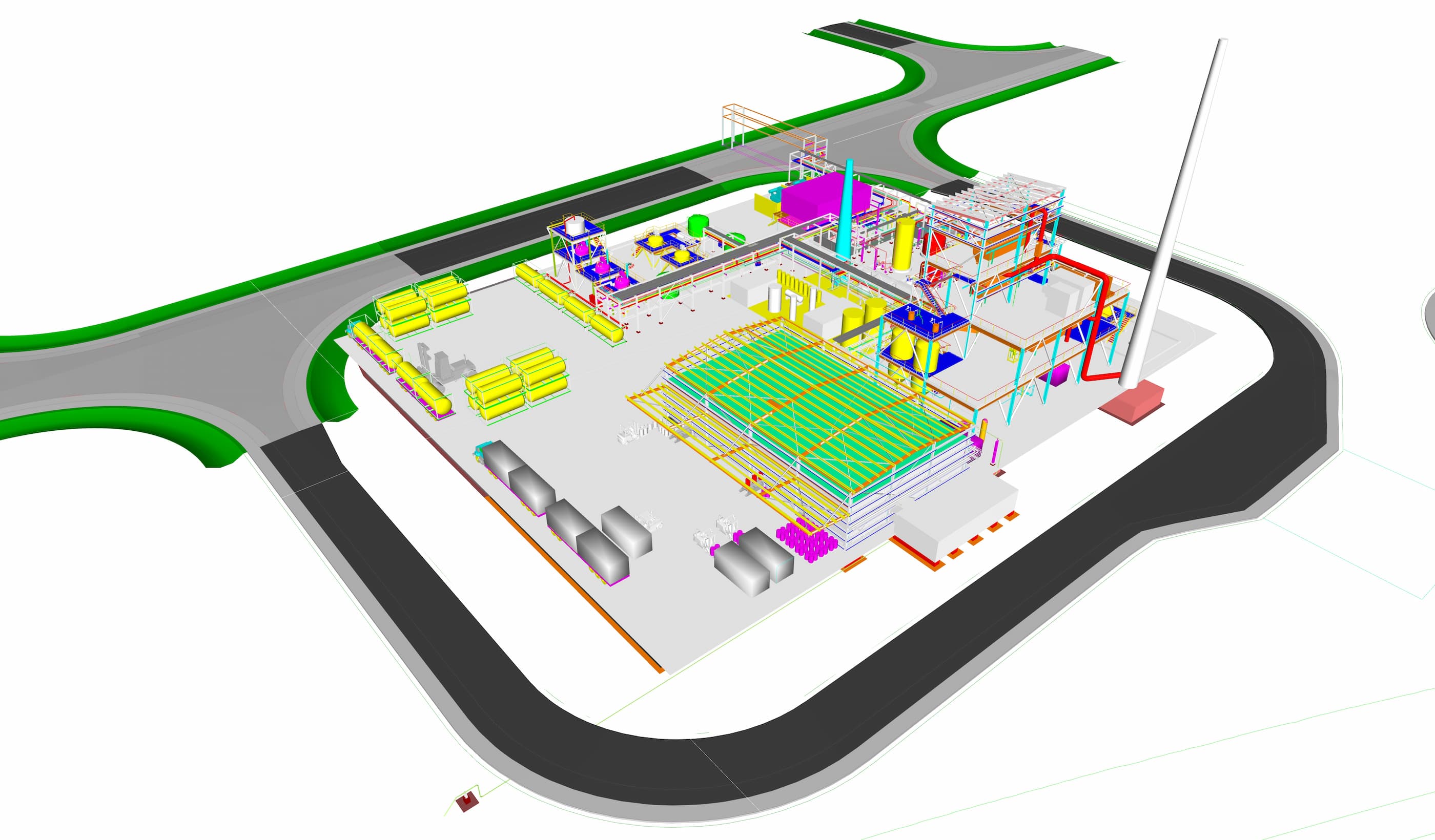

Axle Replacement Inline (ARI) Unit

Historically, replacing wheel axles on iron ore wagons required several hours of intensive labour. There were also health and safety risks associated with jacking a wagon up.

The Axel Replacement In-line Unit (ARI Unit) overcomes several operational issues. Changing axels in a remote location meant designing a solution with minimal infrastructure requirements and high and low-pressure hydraulic circuits needed to be integrated into one hydraulic power unit. In addition, the ARI Unit would be installed in live signaled rail areas under train control, making maintaining rail continuity a primary objective. The construction, fabrication, and commissioning of the ARI Unit was completed offsite and installed in under one week.

The ARI Units use a self-contained solar-charged battery-powered sump pump and hydraulic power unit. It includes a bogie jack locking system, safeguarding the maintainer from the line-of-fire of a suspended load, and a shoeing and brake adjustment bar. In addition to changing axles on iron ore wagons, this system can also be used for heavy haul rail, bulk material wagons, tankers, and container freight wagons.

Two ARI Units were successfully delivered and installed, immediately improving safety by eliminating the need to hoist wagons, and in doing so, saving time. A single wheelset change-out can occur in just 10 minutes in any remote location—including shunt.

- Location

- Western Australia

- Offices

-

- Location

- Western Australia

- Offices

Share

Damian Pianta, Project Manager

There is nothing more satisfying than improving safety for our clients and employees.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.