How two scientists collaborated to develop a tool for better stream restoration design

April 15, 2022

April 15, 2022

New tool generates more alignment options and does it faster, thanks to CAD and computer savvy

What happens when you take two scientists from vastly different disciplines and put them in a room to dream up a design and engineering problem?

For Soojung Kim and Michael Sendelbach, their dream couldn’t even start in a room. Working out of their homes in different time zones, in different countries, and during a pandemic, Soo and Mike were paired to create a better software tool to help restore streams and rivers. Their career paths couldn’t have been more different.

Soo immigrated from urban South Korea to British Columbia to study civil engineering but became a design technology specialist instead. Her early computer career focused on architecture and building design, then spread to other disciplines.

Growing up in a rural environment but a self-described “computer nerd,” Mike also started in civil engineering but eventually focused on environmental engineering. He landed in his dream job in river and stream restoration.

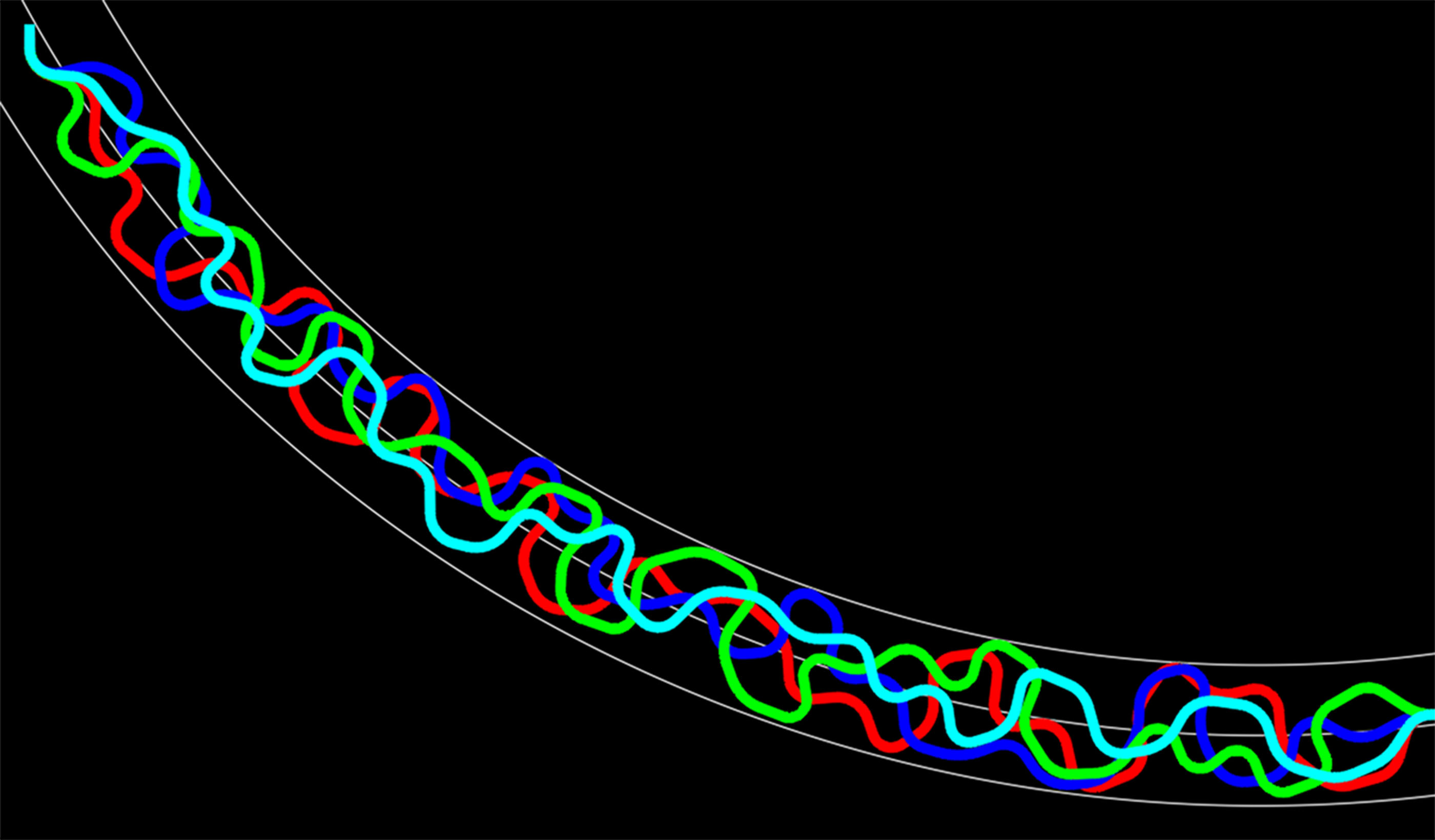

A well-functioning stream design starts with mathematics and engineering. Soojung Kim and Michael Sendelbach spent 16 months collaborating on a new software tool that makes designing river and stream restoration much better.

Soo and her family live in Vancouver, British Columbia; Mike and his family live in Louisville, Kentucky.

Despite their distance, they spent 16 months collaborating on a new software tool that makes designing river and stream restoration much better. Here is the problem they solved: For years, engineering teams have struggled with spreadsheets that refused to play nice with computer-aided design (CAD) tools.

Integrating mathematical equations with CAD modeling tools was clunky and laborious, especially among teams using different spreadsheets. Environmental engineers like Mike wanted software that automated stream designs, fixed spreadsheet issues, and allowed clients to see real-time design variations.

Soo and Mike built that tool, which quickly provides clients with multiple alignment alternatives to a stream design. In doing so, they forged an unlikely collaboration that relied on the universal language of math—and they became friends along the way. Here is their story.

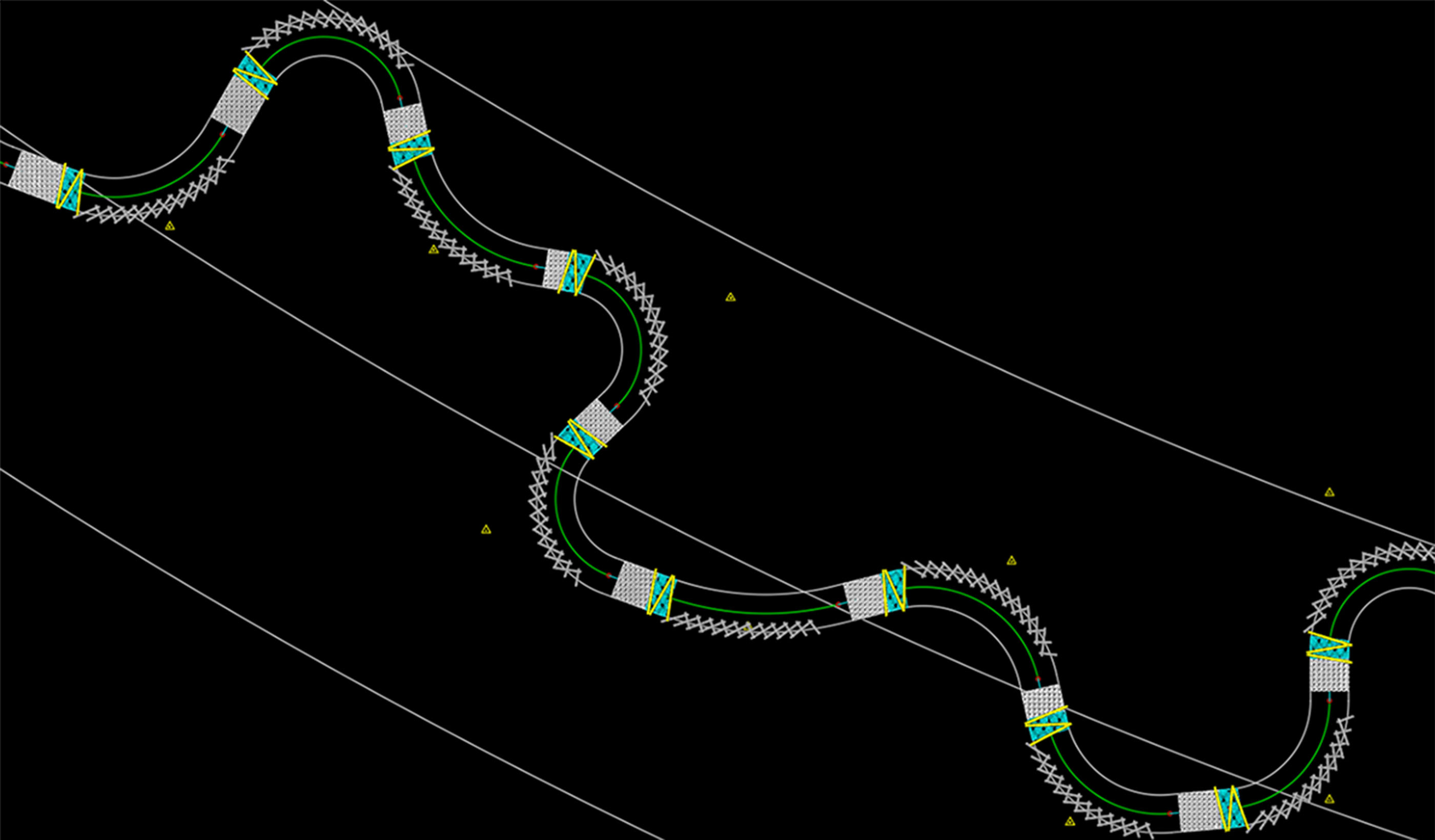

A new Stantec tool automates the process of placing structures in the stream restoration design.

Mike: I was hired at Stantec to work in the FEMA flood mapping group but worked my way into the stream restoration group. The problem Soo and I have been trying to solve is to make our design process more effective. I’ve always had a passion to continuously improve our design tools, but until now, I haven’t been able to take that big step we needed.

Soo: I started working as a BIM manager for our Buildings group here at Stantec and I mostly worked with the architectural and structure group for the first few years. Same as Mike, my focus was to make the design/delivery workflow smarter. Then I decided I wanted to learn about other industries like water, environmental services, energy, and resources, which led me to the Digital Technology and Innovation Group and eventually working with Mike.

Mike: Our problem was that different offices used different spreadsheets for our stream designs and transferring their data into a modeling tool was very tedious. Different spreadsheets didn’t talk to each other. We started on the project with one team, but they couldn’t devote enough time to it. That’s when we were connected to Soo.

Soo: When I work with designers, I asked a lot of questions, like how do you do design now? Why do you want to automate this process? In this case, we didn’t know each other’s areas of expertise, so I wanted to know what Mike does step by step.

Mike: The first question we had was if a programmer didn’t know stream restoration and a stream engineer didn’t know computer programming, how were we going to speak the same language? But it worked out well.

The first question we had was if a programmer didn’t know stream restoration and a stream engineer didn’t know computer programming, how were we going to speak the same language?

Soo: We determined that we had a lot in common, such as math. There was also a lot of geometry that figures into the design.

Mike: Math is a universal language. I remember we screen shared a lot on that, sketching things out geometrically to figure out how we were going to progress from one step to another.

Soo: It is interesting that we didn’t have any obstacles working remotely. It’s easy to share screen and files through Teams. When we were heavy into development, we talked every day.

Mike: Soo was also very responsive and fast to turn iterations around. Communicating over that distance and time could have been difficult if we were not so responsive to each other.

Soo: There is a three-hour time difference between us, so we would often leave messages for each other and work obscure hours on the project.

Mike: Yes. Accommodating family and work life was difficult during the pandemic, so I would end up working later hours anyway.

Soo: What did I learn through this collaboration? This was my first project where I used computational design for civil engineering, but Mike helped me push the limits of my knowledge. I can say now I’m an expert in Civil3D computational design. The collaboration expanded my expertise in this area.

A new tool designed by Soojung Kim and Michael Sendelbach quickly provides clients with multiple practicable alternatives to a stream design.

Mike: One of the things that came out of our collaboration is a tool that can quickly generate multiple alignment alternatives to stream design. In the past, it could take hours to generate alignments within specified design parameters. We can now quickly generate multiple alignment alternatives for the engineers and clients to choose from that are based in sound engineering and natural channel design principles.

Soo: We’re almost done with development and we’re just in the process of final user testing and debugging a few things. Looking back, I can say it was fun and rewarding; I feel like I made a good friend in Mike.

Mike: I agree. It was a lot of fun and I hope it doesn’t end here. I look forward to working with our clients to apply the tool to real-life designs!