At a Glance

-

4K

TPA High Purity Alumina

- Location

- Townsville, Queensland

- Offices

-

- Location

- Townsville, Queensland

- Offices

Share

High Purity Alumina Definitive Feasibility Study

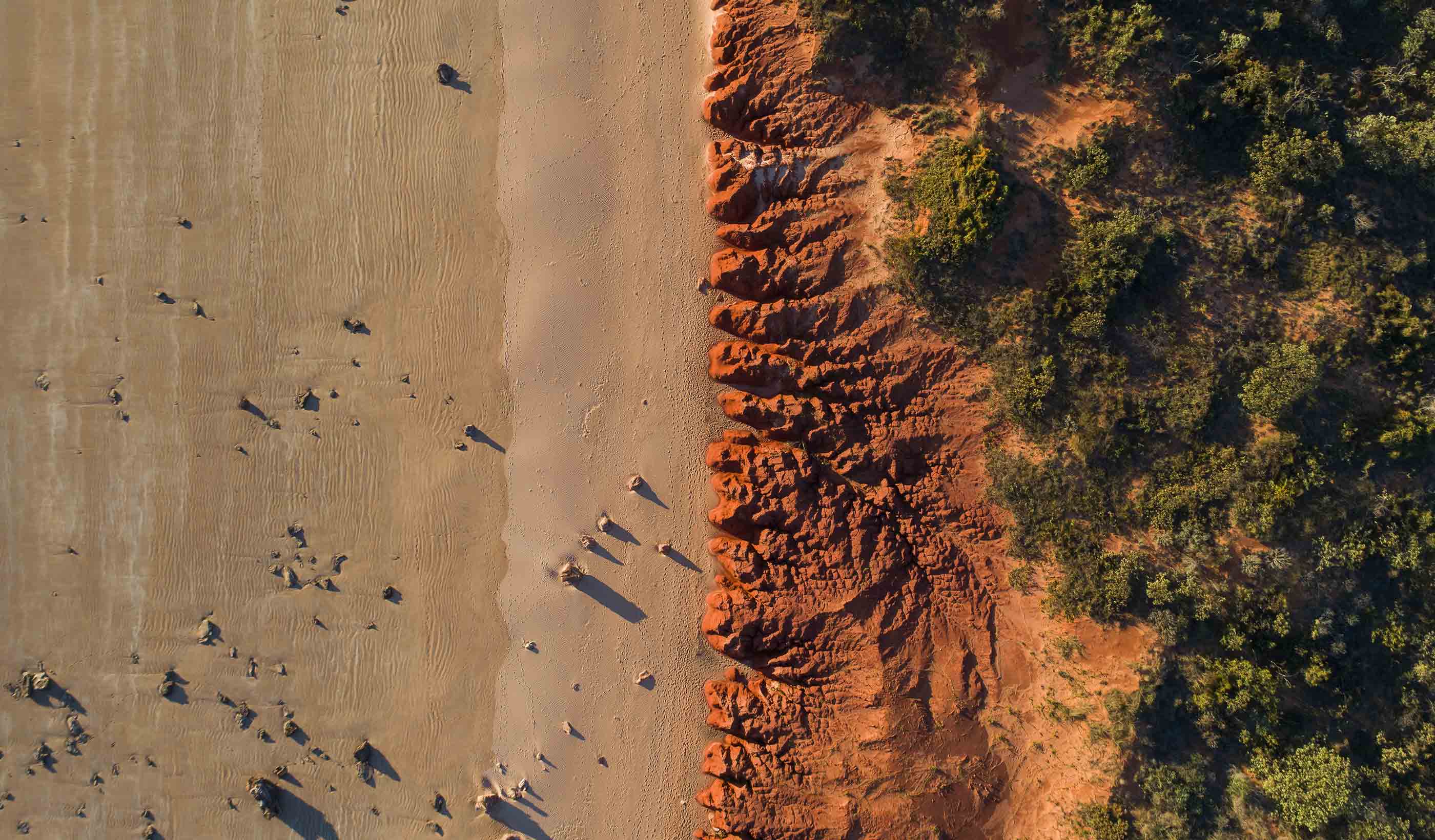

To aid its decarbonisation journey, the world needs high purity alumina (HPA) and we’re helping to design a way to process it. How is HPA used? It’s used to produce synthetic sapphire, a type of scratch-resistant glass, as well as lithium-ion batteries that are critical for use in electric vehicles and solar battery storage. We worked with technology developer Lava Blue and QUT to scale the science—moving from the laboratory to a demonstration plant processing 20 kilogram batches.

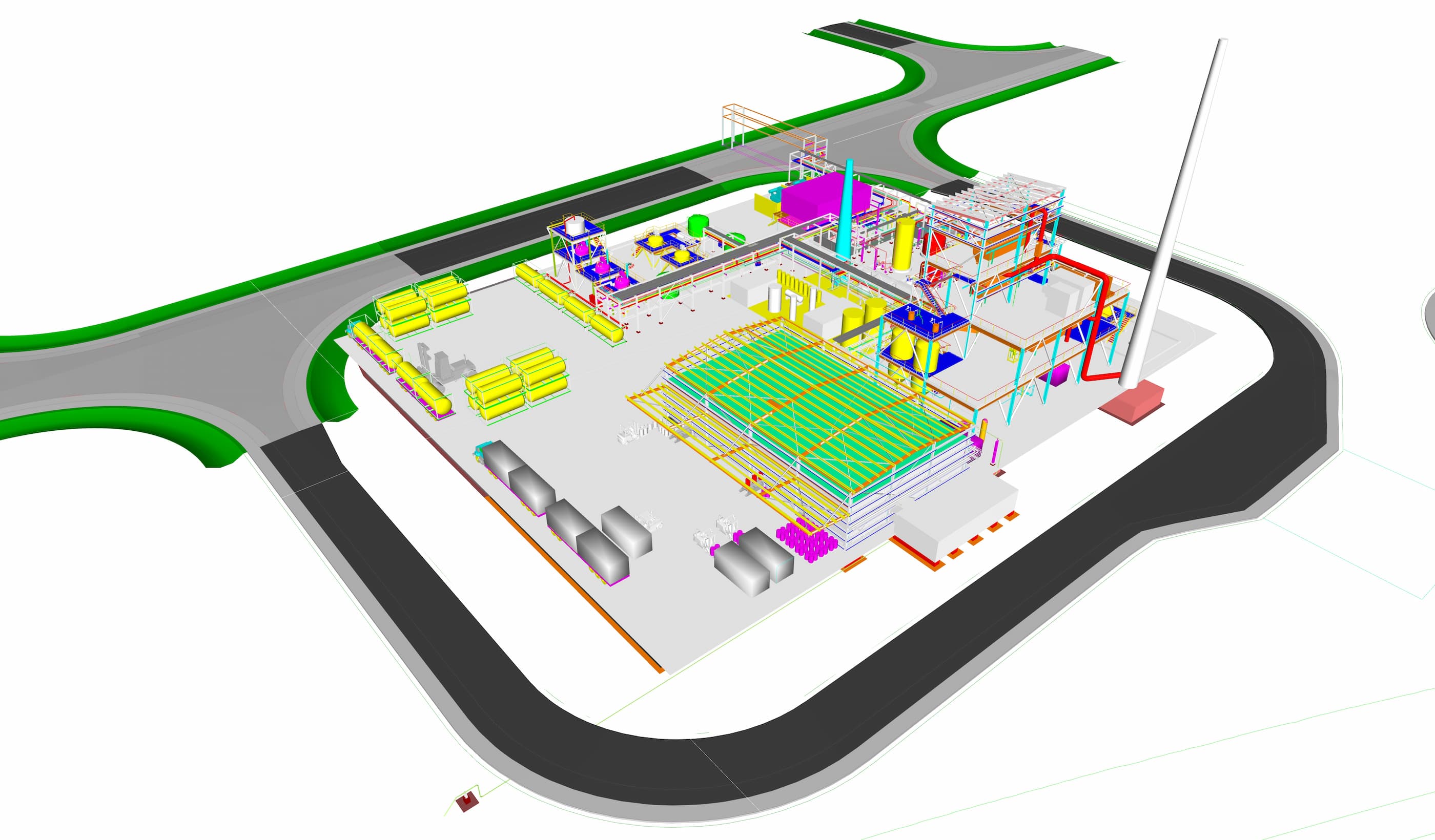

Thanks to an agreement with Lava Blue to use this technology, we’re now developing a four thousand tonnes per annum (TPA) commercial scale HPA operation for a client. As part of the project’s definitive feasibility study, we’re undertaking the engineering and design of the plant. To support a Class 3 capital cost estimate, or budgetary estimate, we ascertained the plant’s footprint, then modelled it in 3D to demonstrate the layout and quantities. The project was managed by our Mineral Processing Centre of Excellence in Brisbane which provided a full suite of disciplines including process, mechanical, electrical instrumentation, and controls (EI&C), civil, and structural engineering.

Following this project, we engaged in a prefeasibility study for a smaller, commercial scale HPA plant for another client—helping to decarbonise the world, one project at a time.

At a Glance

-

4K

TPA High Purity Alumina

- Location

- Townsville, Queensland

- Offices

-

- Location

- Townsville, Queensland

- Offices

Share

Damian Pianta, Project Manager

There is nothing more satisfying than improving safety for our clients and employees.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.